Main Applications of Ozone

―Surface Modification―

Improvement of the quality of packaging materials

Enhancement of the productivity of lamination using ozone

- Effects of ozone

-

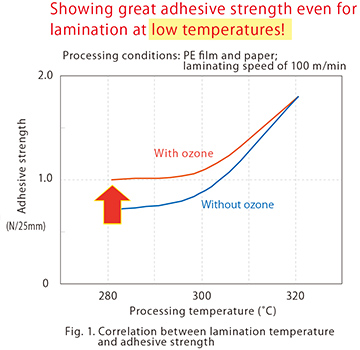

- Increased adhesive strength

- Reduced damage of materials; reduced consumption of energy due to decreased temperature required for processing

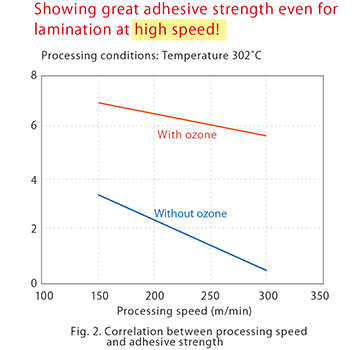

- Increased processing speed

- Reduced plastic odor

- Decreased loss of materials; improved workability due to the shortened air-gap

<Comparison between with and without ozone for extrusion lamination>

<Application examples>

- Foods (packages for candies, soups, etc.)

- Medical care (packages for pharmaceuticals, etc.)

- Construction materials (wallpapers, etc.)

Ozone generation system for lamination

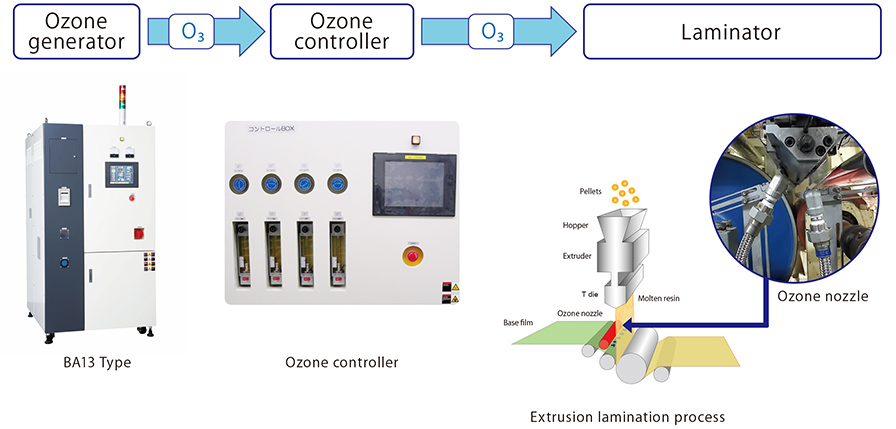

<Ozone generation flow>

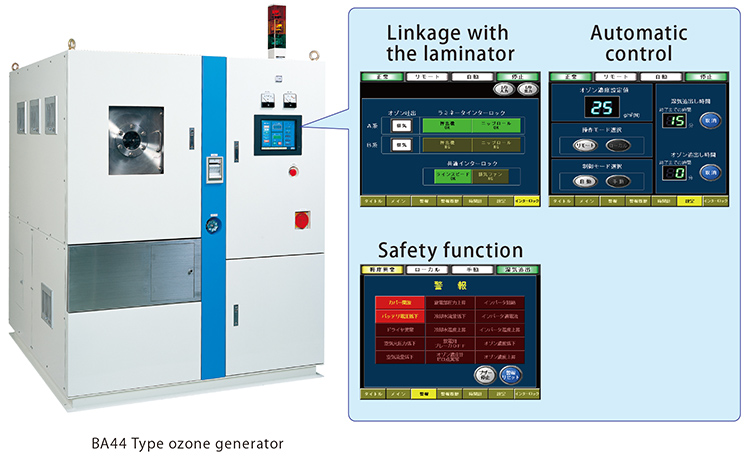

<Features of our ozone generators for lamination>

- High concentration and flow rate, suitable for lamination

- Safety-first design

- Automatic control in linkage with the laminator

- Abundant delivery records

<A wide range of lineup>

| Type | Ozone gas generation g/h | Ozone gas flow rate m³/h(N) |

|---|---|---|

| BA4-80-25 | 80 | 3.2 |

| BA7-140-25 | 140 | 5.6 |

| BA13-240-25 | 240 | 9.6 |

| BA20-380-25 | 380 | 15.2 |

| BA29-540-25 | 540 | 21.6 |

| BA44-800-25 | 800 | 32 |

See details of product: BA Series